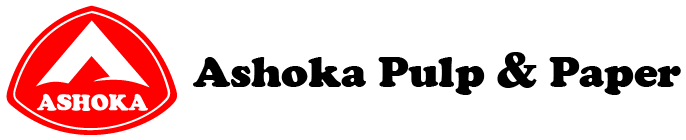

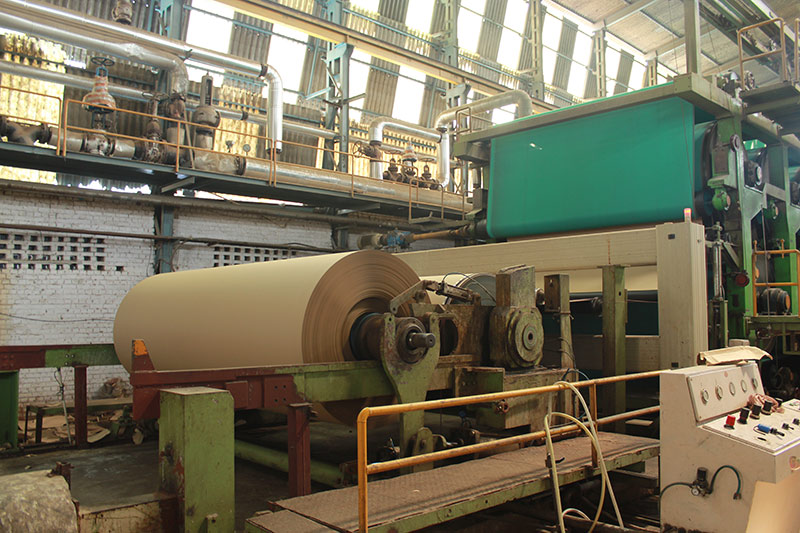

Machinery

- Ashoka Pulp & Paper takes pride in having the state of the art machine equipment for manufacturing high-quality Kraft Paper

- All our machines including Pulp Mill, Multiple wire Paper Machine, Pressure Screens, Jumbo Press, Sheet Cutters, High-Speed Globe Re-winders, and Packing and Shrink Machines are maintained to their optimal efficiency.

- Machines with various Deckle Sizes are in place for the production of Test Liner and medium/Fluting Medium Paper

| Machine | Deckle | Machine | Deckle |

|---|---|---|---|

| PM 1 | 2700mm | PM 3 | 3000mm |

| PM 2 | 3600mm | PM 4 | 3900mm |

Quality Control Equipment

- Our manufacturing and processing units are equipped with Digital Quality Control Equipment for ensuring product quality compliance.

- All the equipment is automated and functional with a PLC system minimizing human involvement. Fully Digitized and Automated QCS and DCS are in place.

- State-of-the-art indigenous and imported machinery for producing the best quality Kraft Paper (Medium and Liner Paper).

Material Handling Equipment

- Our Materials and Products are handled and managed smartly with good quality machinery and equipment – Electric Pallets, Forklift Trucks and overhead Cranes for the swift and safe movement of goods.

Uninterrupted Supply of Power

- All our 3 units are equipped with individual Captive Power Plants ensuring 24 hours supply of power leading to constant optimized production.

| Machine | Deckle | Machine | Deckle |

|---|---|---|---|

| PM 1 | 2700mm | PM 3 | 3000mm |

| PM 2 | 3600mm | PM 4 | 3900mm |

R&D Lab

We have invested in innovative research facilities and cutting-edge technology. We use state-of-the-art tests and trials to test various parameters of the paper at various stages.

Ashoka Pulp & Paper has committed Lab Technicians who have continually focused on R&D activities for enhancing product portfolio and augmenting product features.

We have installed advanced testing facilities to test various relevant product Parameters – BF, BS, Moisture, Cobb to be able to cater to global standards quality parameters.

Water Facilities

We are equipped with an adequate supply of clean water for manufacturing paper.

Effluent Water Treatment Plant

In conformity with our vow to preserve the ecological resources for future generations, our premises are equipped with a state-of-the-art effluent treatment plant for water treatment and its reuse for paper production. In this way, we conserve water and also endeavor to mitigate excesses of pollution. Effluent treatment results in odor-free paper as well.

Storage facilities

Our units have a large raw material storage facility for maintaining sufficient reserves for consistent delivery of quality products.

We adopt scientific analysis for optimizing operations, conserving the environment, and delivering the best products, thereby, giving 100% efficiency to everything that we do. In this manner, we ensure gaining valuable customer trust while adding value to human life through ecologically friendly operations.